Contact number:

4008-168-880

13714053430

Contact number:

4008-168-880

13714053430

|

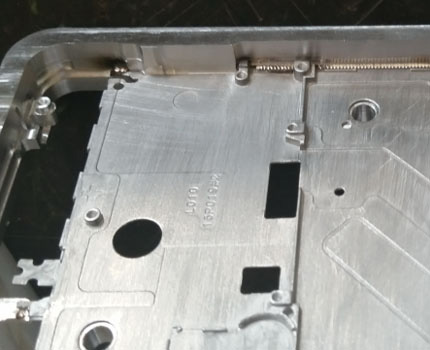

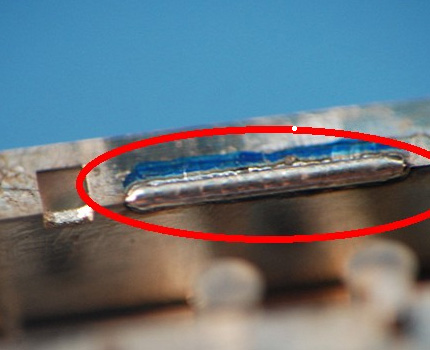

Laser welding of mobile phone shell At present, ultra-thin mobile phone has become the mainstream, the original use of stainless steel main frame gradually replaced by aluminum whole plate CNC processing, the main frame processed by aluminum, reflects the advantages of not easy deformation, light weight, easy anode treatment, but because the plate is not easy to CNC processing, so the use of laser welding external frame and plate laser welding, Solve the problem that CNC can not be processed. The optical fiber transmission energy feedback laser welder developed by Tongfa has excellent welding performance for aluminum, high energy and more stable processing performance in high-power welding aluminum. |

|

|

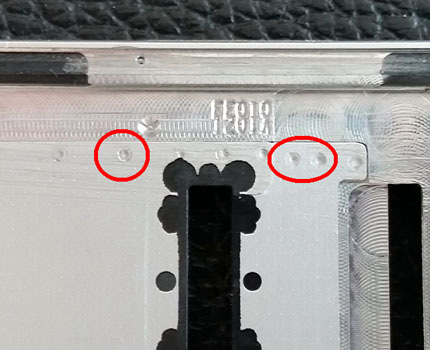

Aluminum mobile phone frame and plate laser welding Aluminum mobile phone frame and plate overlap welding, stainless steel has superior laser welding performance, aluminum welding is much more difficult than stainless steel, because aluminum laser absorption and heat dissipation performance determines the difficulty of welding is higher. The optical fiber transmission energy feedback laser welder developed by Tongfa Laser has excellent welding performance, stable firmness and beautiful welding appearance for aluminum. |

|

|

|

|

Laser repair welding of large molds for automobile household appliances For large molds, the laser head is installed on the boom system, and the joystick controls the electric XY biaxial movement. At the same time, the lifting of the boom system is also carried out by the DC motor, which realizes the 3-dimensional movement of the curve. Solve welding large mold such as: household appliances plastic mold, automobile injection mold laser repair welding. |

|

|

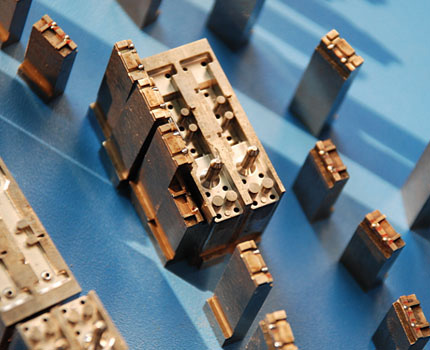

Laser repair welding of precision plastic mold Commonly used plastic mold steel such as: S136, NAK80, 718, 738, P20, 2316, 2083, S-STAR and so on. The Pass-fa mold laser welding machine can be used to repair the laser welding of different materials of plastic molds. Because of the inconsistent brand of materials in various countries, the composition of some materials is close to that of others, which can be universal. For example, the mold encounters the cutting error of the knife, the EDM processing is too deep, the impact damage of other hard objects, the error of the flower biting processing, the sand hole of the mold material itself, the mold collapse caused by the plastic is not pushed out in time in the process of mold production, the wear of the mold when the injection molding for a long time, etc. The damage caused by these problems can be repaired by the pass-through laser welder. |

|

|

|

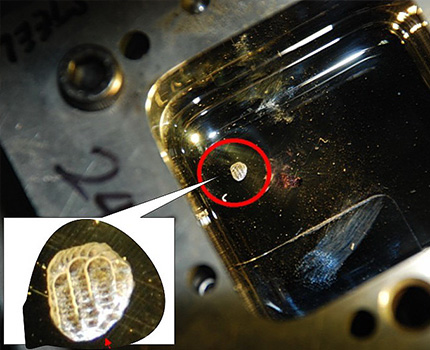

Precision plug-in laser welding Precision plug-in of plastic mold is the core of plastic mold. Because it is arranged and combined by multiple inserts, it has higher requirements on the shape and size of the plug-in mold core. At the same time, the cavity of the mold core is processed by EDM EDM forming, and the workload is numerous and complicated. Will recover greater losses. The mold laser welder developed by Tongfa Laser has almost perfect repair to the precision plug-in mold core. The hardness after welding is consistent with the mold core. The narrow seam, sharp Angle and deep groove can be repaired precisely without burning other parts. |

|

|

Laser repair of mirror plastic mold The laser welding machine can carry out the laser repair work on the mirror plastic mold. After repair, the mirror effect of the mold material can be achieved by polishing. When the laser repair is done, the hardness of the repaired material should be basically the same as that of the original material, and the appropriate welding wire should be selected. |

|

|

|

|

Laser welding for kitchen heating Stainless steel is one of the materials with better laser welding effect. The pass-fah laser welding machine has fundamentally changed the defects of the traditional welding process, such as product deformation, blackness, unfirm welding, high welding cost and time-consuming and laborious welding follow-up processing. Especially in high-end stainless steel products such as stainless steel bathroom kitchenware, stainless steel sheet and stainless steel pipe products such as laser welding technology has been widely used, laser welding can be easily automated according to customer requirements, and the machine durable time is long, for the mass production of products is undoubtedly a big advantage. Compared with the traditional welding process, the low-power pulsed laser seam welding has the advantages of high power density, energy concentration, small heat input, narrow weld and small deformation, and the laser beam focusing can obtain a small spot, precision positioning, these characteristics make laser seam welding more suitable for the welding of small size workpiece than other welding methods. |

|

|

Auto parts laser Laser welding machine can weld different materials of metal products, such as: copper, iron, aluminum, stainless steel, carbon steel, galvanized sheet, titanium alloy and so on, these metal products cover: electronics, electrical appliances, construction, automobile, aviation, military, daily necessities, packaging and other different fields. The welding of auto parts needs to be firm, precise, beautiful and fast. The automatic laser welding machine developed by Tongfa Laser is a sharp tool for welding processing of such products. |

|