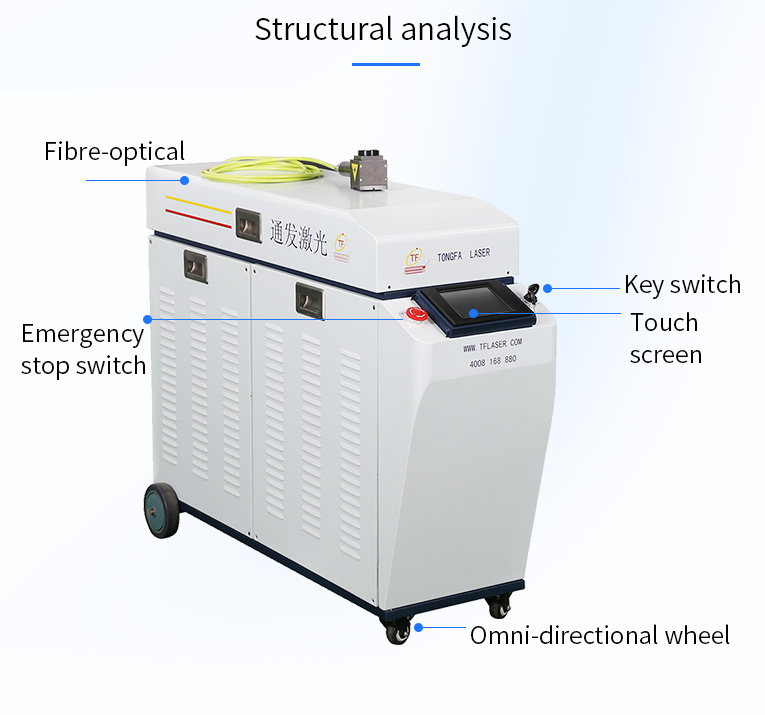

Optical fiber laser welding machine is a kind of laser welding equipment that couples the high-energy laser beam into the optical fiber, transmits from a long distance, then collimated into parallel light, and then focuses on the workpiece. For the inaccessible parts, flexible transmission non-contact welding has greater flexibility. It is currently used in sheet metal manufacturing, battery sealing, auto parts and other industries. Optical fiber transmission laser welding machine laser beam can realize the separation in time and energy, can process multiple beams at the same time, providing conditions for more precise welding.

Fiber laser welding machining sample picture

Gold ring laser Welding

|

|

Platinum ring for laser welding

|

Gold pendant by laser welding

|

|

Laser repair welding of gold finger ring

|

Laser welding of the silver pendant

|

|

Gold-set jade laser welding

|

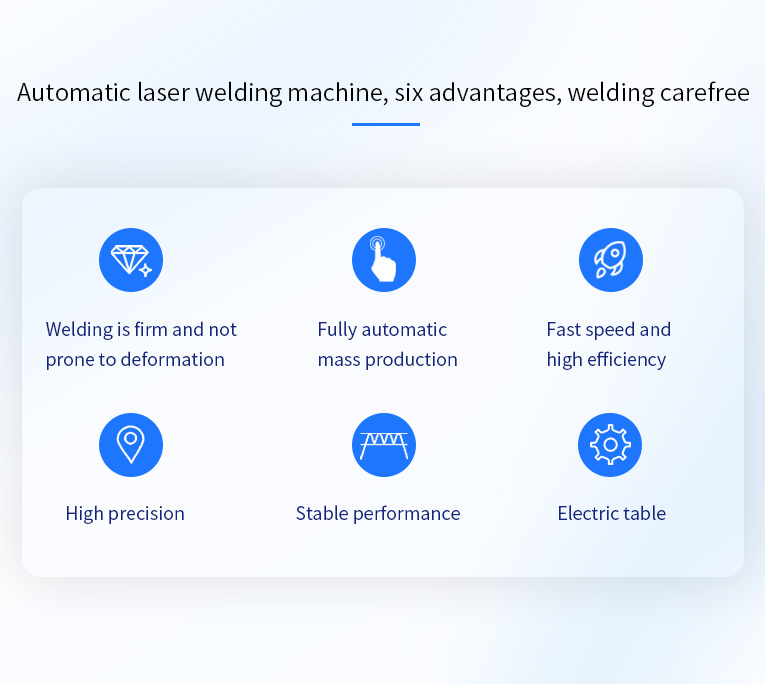

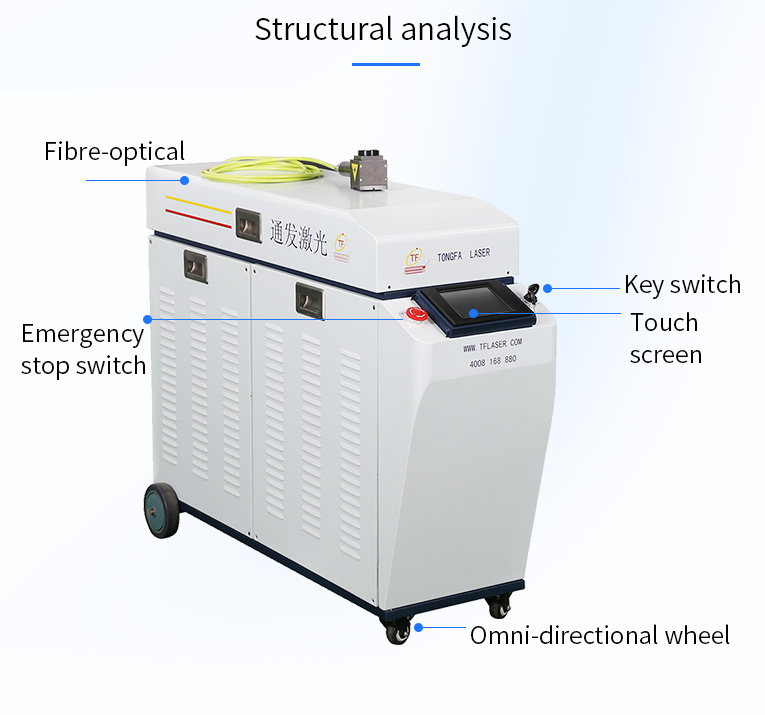

Applied range

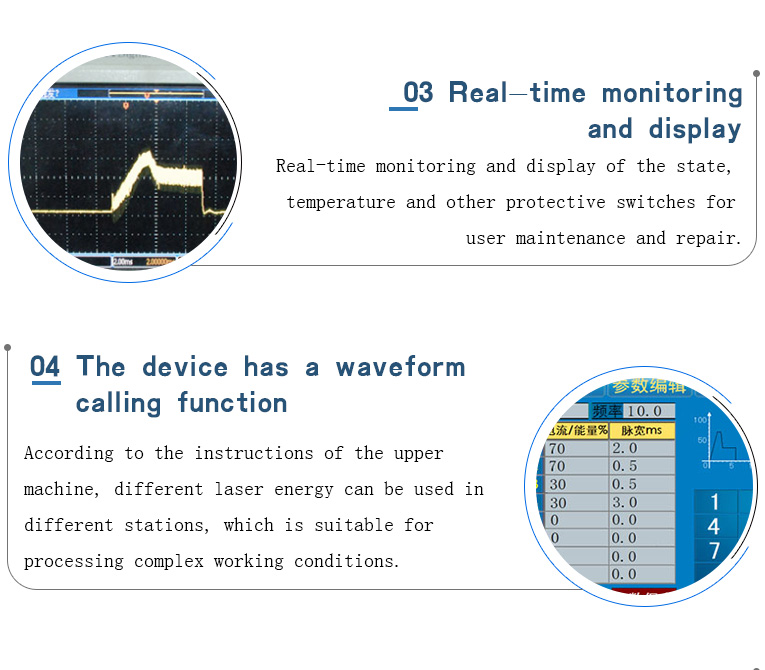

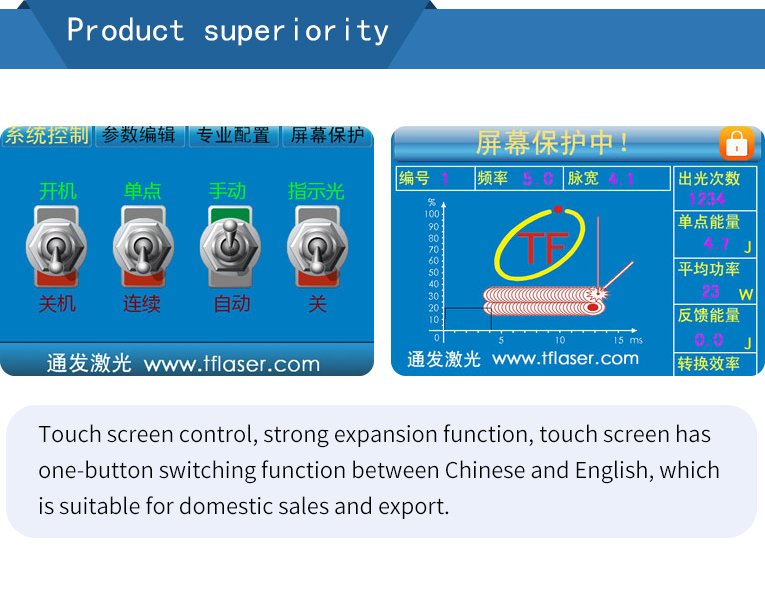

Hair laser research and development for with gold chain machine, K gold chain machine, jewelry chain machine, necklace chain machine TFL-40 PF automatic fiber laser welding machine, welding machine using energy feedback technology, light stability, strong energy, and installation, realize the function of a ring welding, to ensure the tensile strength of gold chain, can be widely used in spot welding and flexible processing demand industries such as welding. This laser welding machine realizes the miniaturization structure of integrated air cooling. Applicable for various production sites.

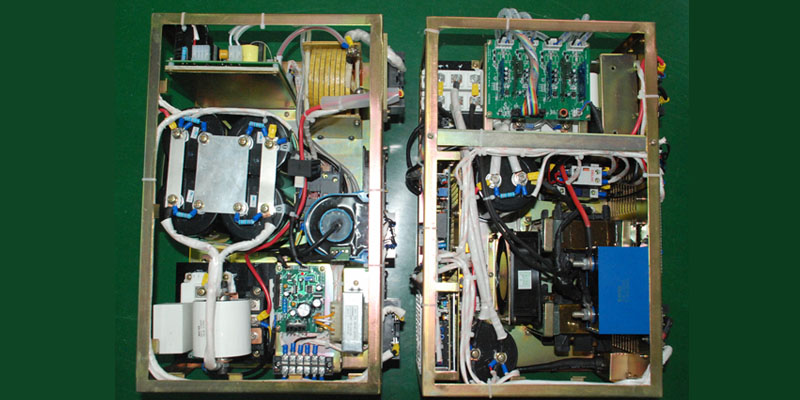

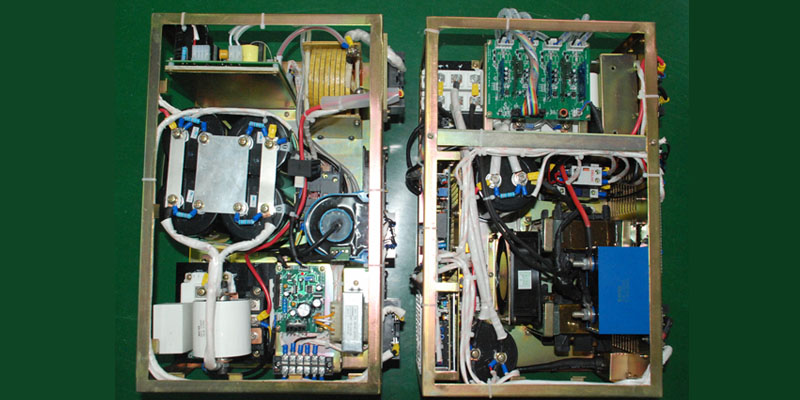

Precision power supply

1. The equipment adopts the boost power supply, which is not affected by the fluctuations of the power grid, and the single-point energy output capacity of the power supply is also stronger.

2. The power supply of the equipment adopts the shunt design, which diverts the large heating components to several roads for control, effectively reducing the heating power of the power supply.

3. The power supply of the equipment adopts the imported IGBT to ensure the quality.

4, the laser power supply adopts high power isolation conversion technology, the human body touches any discharge part will not be electric shock, the safety is improved.

5, laser high current discharge has hardware and software over-current protection lock and alarm.

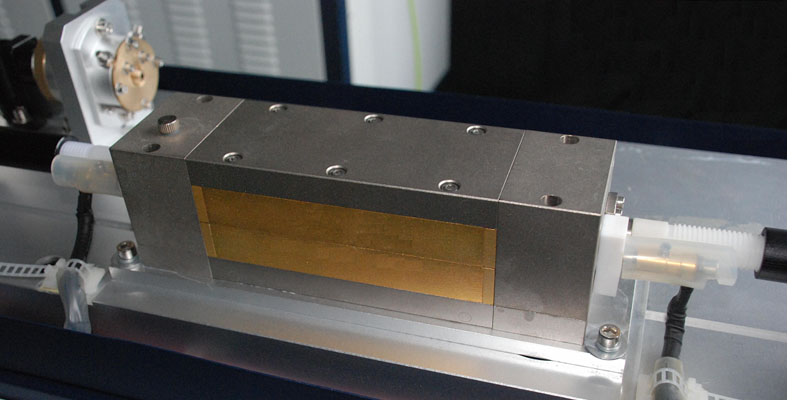

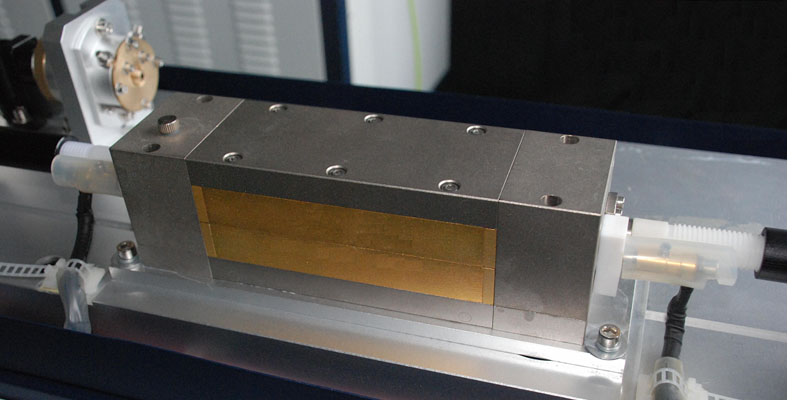

Core light device

1. The laser rod adopts the new YAG laser rod, optimizes the parameters of the laser rod, and improves the laser photoelectric conversion efficiency, which is better than the single point energy and beam quality of the ordinary laser rod.

2. The laser cavity is separated by xenon lamp and laser rod, and changing the lamp does not affect the light path.

3. The use of overlapping reed frame, more stable than the ordinary pull spring frame, light output is more stable.

4. the lens are military-grade coating, more durable than ordinary lenses.

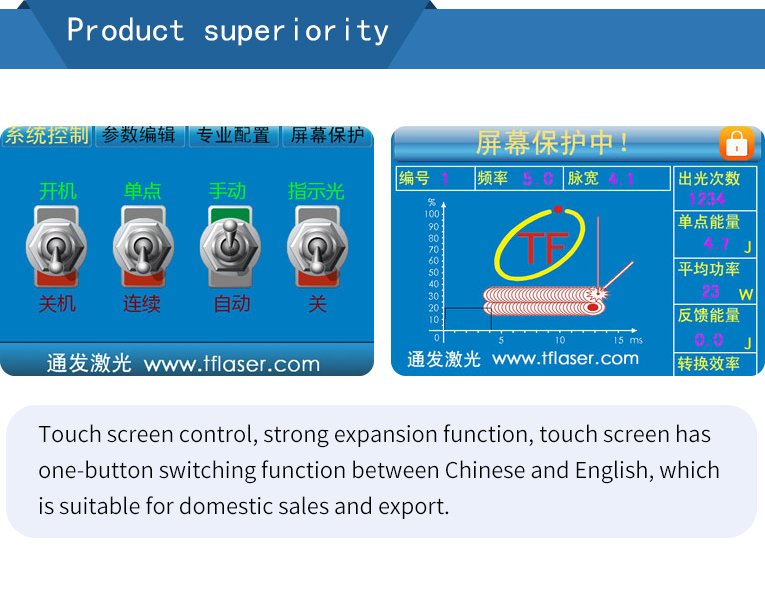

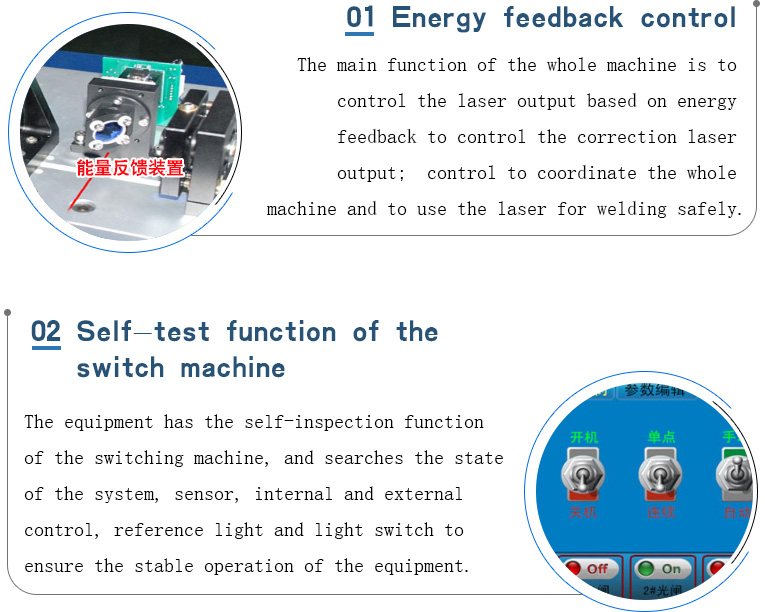

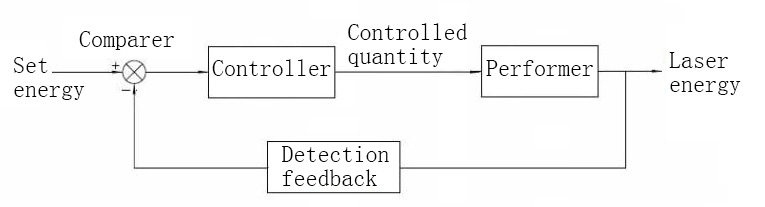

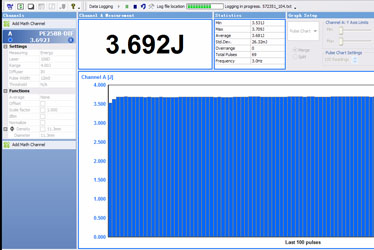

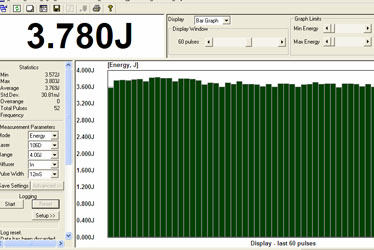

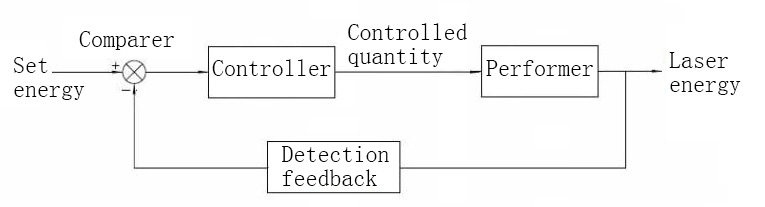

Precision feedback control system

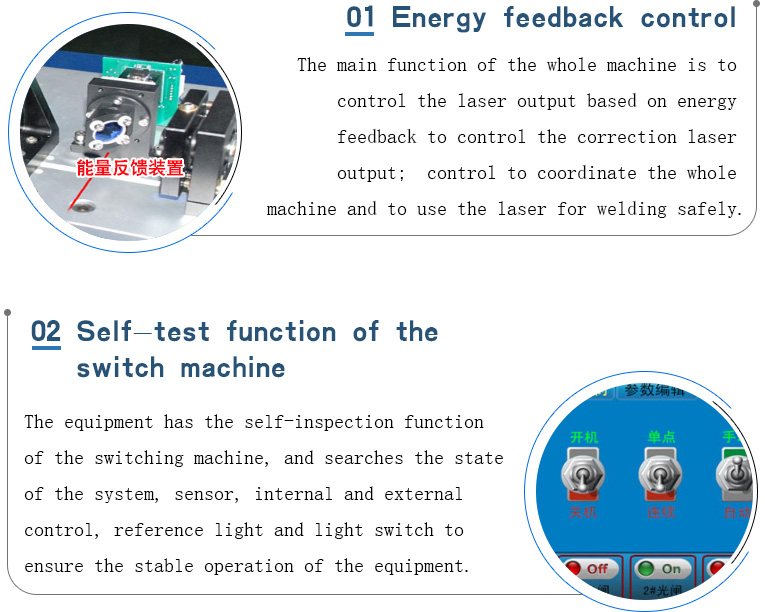

Energy feedback system: Energy feedback belongs to the negative feedback system, and the laser output is controlled in real time through the negative feedback signal of the light path.

Patent of power supply pulse current overcurrent protection device and optical fiber laser laser welding machine fast time light separation device

Various functional devices can be selected

|

|

Gold jewelry chain loom

Accessories description: universal magnetic seat with powerful magnet function, by the switch adsorption and release material, main adsorption below 10 KG of steel mold and parts, and can any rotation Angle, makes the mold need to repair welding position can be easily placed in the position of laser easy irradiation, especially for small parts, greatly improving the efficiency of repair welding. |

|

|

Laser welding machine desktop four-axis automatic workbench

The workbench can be linked with four axes to realize the spot welding of the curved surface. |

|

|

Laser welding machine vibrator workbench

Laser welding machine lens workbench configuration high speed biaxial scanning lens, efficiency is electric workbench welding speed 2-5 times, especially suitable for superposition without argon protection or weld laser welding, the popularity of smart phones and internal stainless steel frame and aluminum frame, laser welding in mobile phone hardware welding industry has been widely used. |

Attachment and consumables

|

|

Laser pulse xenon lamp

Pulse xenon lamp chooses high quality ultraviolet filter quartz tube as the tube material, with high mass density electrode as the electrode of xenon lamp, has strong load capacity, high pump efficiency, good laser beam quality, long life and other characteristics.

|

|

|

Laser welding machine protects the lens

Mainly protect the high value of the focus lens. Avoid welding smoke splashing and dust pollution to the lens lens. |

Product Parameter

|

Model |

TFL-40PF |

|

Laser wave length |

1064nm |

|

Laser power |

40W |

|

Laser pulse energy |

60J |

|

Optical fiber output quantity |

1 Road |

|

Feedback system |

Energy feedback |

|

Pulse length |

0.2-12ms |

|

Impulse frequency |

0.4-100Hz |

|

Welding point size |

0.4-2mm |

|

Rate of change of the laser energy |

<±1.5% |

|

Power consumption of the host |

≤3KW |

|

Electricity demand |

AC220v±10%/50Hz,15A |

|

Cooling-down method |

Integrated air cooling |

|

Overall dimensions of main frame (length * width * height) |

400×1150×850 |