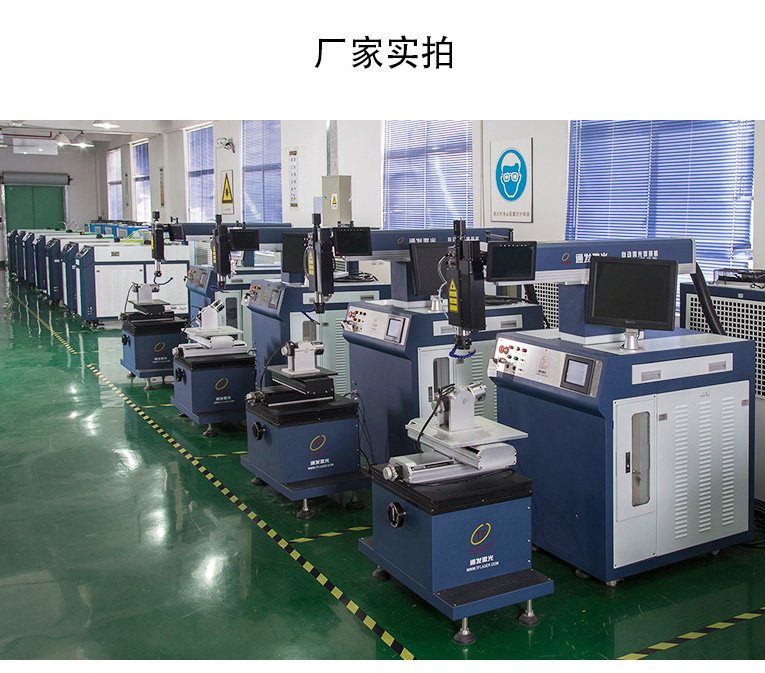

Automatic laser welding machining sample pictures

Kitchen and bathroom bath equipped with laser welding

|

|

Wine pot laser sealing welding

|

Laser welding for plumbing products

|

Laser welding machine protects the lens

Mainly protect the high value of the focus lens. Avoid welding smoke splashing and dust pollution to the lens lens.

|

Lock core laser welding

|

Sensor laser welding

|

|

Printer scraper for laser welding

|

Applied range

TFL-400V / 500V-3D laser welder is a high stability, high power welder, to meet the needs of long time production. High-power laser power supply, high power heat dissipation system to meet the 24 hours of mass production. The fuselage adopts a high-strength structure to ensure the accuracy and stable performance. Control system is a professional 4-axis control system tailored for laser welding, with high stability, easy to learn and easy to use. Strong scalability, can be combined with the assembly line, photoelectric sensors, pneumatic fixtures and other combinations of automatic unattended processing.

Scope of application: bathroom industry: water pipe joint, variable diameter joint, three links, valve, flower head 3 dimensional, space curve welding.

Battery industry: laser welding of lithium battery, battery pack and electrode.

Glasses industry: stainless steel, titanium alloy and other materials of glasses buckle, outer frame and other positions of precision welding.

Hardware industry: impeller, kettle, handle, etc., complex stamping parts, casting parts welding.

Professional laser power supply control system

1. The function of the whole machine is based on the adjustment of the output current, to control the correction laser output, so as to safely and effectively use the laser for welding;

2. The main controller adopts the new ARMv 7 series processor, which has a high processing speed to meet the real-time control of the equipment. Fast and high-precision control and protection of the laser machine. As far as possible to provide customers with a fast and safe use of the experience.

Main interface of common transmission laser power supply |

|

Main controller of the common transmission laser power supply |

3. The use of touch screen to do human-computer interaction, intuitive interface, clear display, various parameters are easy to understand and adjust, simple and easy to use;

4. The software has a strict control logic, fine digital filtering, fast control algorithm, so that the laser output is stable, fast.

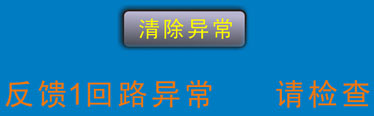

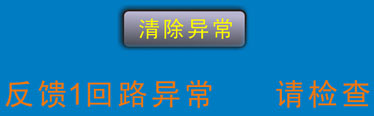

Open laser power alarm interface

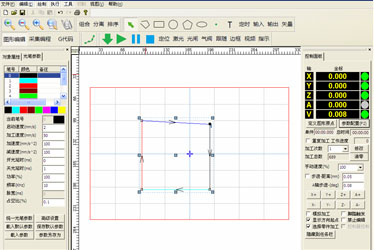

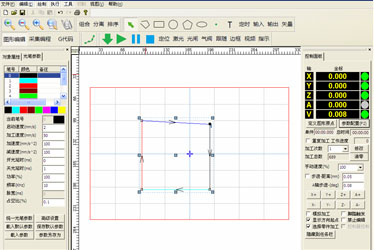

1. Use the mature solution of industrial motion control to integrate the laser welding machine and motion control into the PC operation interface of the machine.

2. Powerful PC control, easy to program, debug and maintain. Can complete automatic or semi-automatic spot welding, butt welding, stack welding, sealing welding, for the complex plane straight line, arc and any track of welding.

3. The software adopts IDE integrated working environment, and the main interface integrates graphic editing, operation monitoring, acquisition and programming, and motion control. The layout is simple and professional, which can effectively improve work efficiency.

4. Real-time control, without other PC operating system plug-in.

5. High performance motion control can be carried out on the 4 axes to realize the programming of welding trajectory in space.

6. Provide multi-language display (simplified Chinese, English, etc.), and support international applications.

Laser PC motion control card

|

|

Laser machine welding machine software operation interface

|

Laser machine welding machine software operation interface

|

|

Laser machine welding machine software operation interface

|

Core laser

1. TFL-400V / 500V-3D consists of dual-way xenon lamp pump, imported ceramic reflective chamber and Nd: YAG crystal rod, with high electro-optical conversion efficiency.

2. The longer laser rod can achieve enough welding energy.

3. Aspherical mirror focus to make the spot smaller and more uniform, and the welding deeper.

4. The laser cavity type is longer, to obtain a good beam quality, more uniform welding.

5. The laser cavity with xenon lamp and laser rod separation design, changing the lamp does not affect the light path.

6. The use of water-cooled mirror frame, which is more stable than the ordinary light path output.

7. The semiconductor red light indicates the positioning.

Gold-plating chamber on the fully automatic laser welding machine

|

|

Cold mirror frame on the fully automatic laser welding machine

|

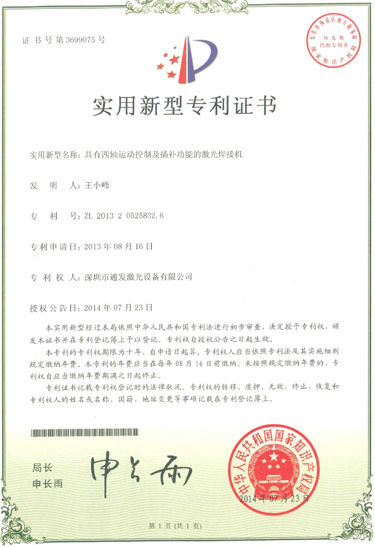

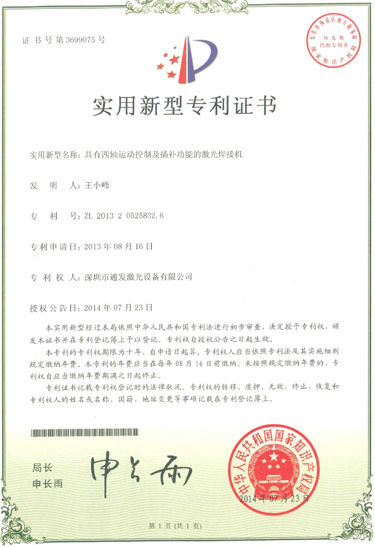

Quadruft motion control insertion function and automatic elimination of solid state laser thermal lens effect device patent

Standard workbench

|

|

Laser welding machine electric workbench

The workbench can choose either a stepping motor or a servo motor. Optional X * Y bench length: 250 * 150 (standard), 300 * 200,400 * 200.

|

|

|

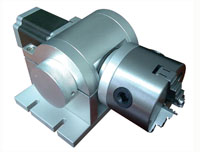

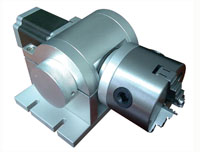

Laser welding machine rotating shaft

The rotating shaft is optional for a stepping motor or a servo motor.

|

|

|

Laser welding machine rotating plate

The rotating disk can a stepping motor or servo motor.

|

Attachment and consumables

|

|

Laser pulse xenon lamp

Pulse xenon lamp chooses high quality ultraviolet filter quartz tube as the tube material, with high mass density electrode as the electrode of xenon lamp, has strong load capacity, high pump efficiency, good laser beam quality, long life and other characteristics.

|

|

|

Laser welding machine protects the lens

Mainly protect the high value of the focus lens. Avoid welding smoke splashing and dust pollution to the lens lens.

|

|

|

Open laser chiller filter element

The main function of the filter element is to remove solid, colloid and other debris in the water, clean the cooling water, and protect the laser.

|

Product Parameter

|

Model |

TFL-400V-3D |

|

Laser wave length |

1064nm |

|

Concentration cavity reflector |

Golden cavity |

|

Rated laser power |

400W |

|

Maximum laser power |

420W |

|

Pulse length |

0.1-20ms |

|

Laser frequency |

1-100Hz |

|

The scope of light spot regulation |

0.3-3mm |

|

Aiming at positioning |

Red light (optional camera system or microscope) |

|

Positioning accuracy |

±0.02mm |

|

Cooling power of the water chiller |

5P |

|

X, Y axis itinerary |

200mm×300mm (customizable) |

|

Z axis itinerary |

150mm (customizable) |

|

Spin axis size |

φ60φ80φ120φ200(customizable) |

|

Power rating |

16KW |

|

Electricity demand |

380V±5%50Hz/40A |

|

Outline dimension |

Main engine:760X1600X1500mm

Cooling-water machine:660X1300X1200mm |