Pictures of TFL-400III Told

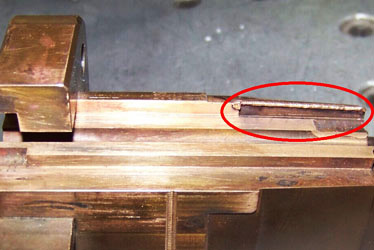

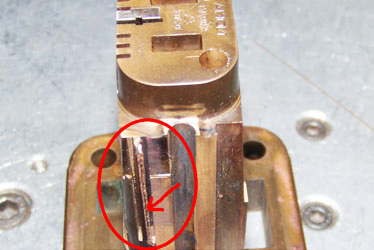

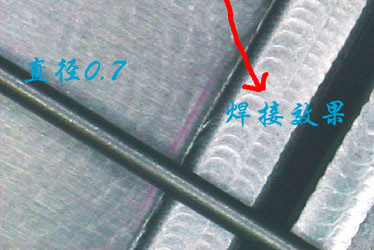

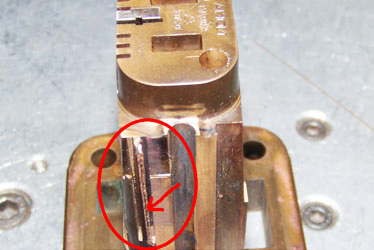

High-power laser burn welding of beryllium copper mold inserts |

High-power laser burn welding of beryllium copper mold inserts |

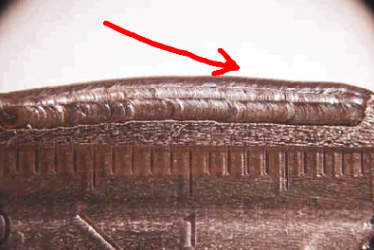

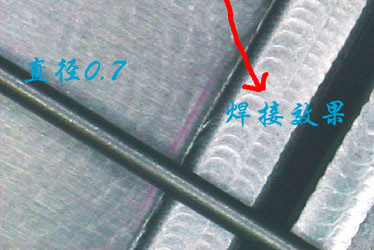

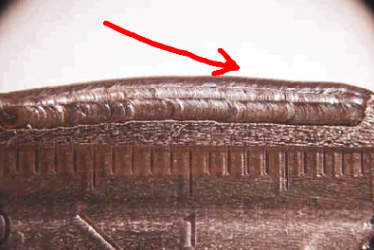

Superior high-power laser welding effect |

High-power laser welding of purple copper electrode |

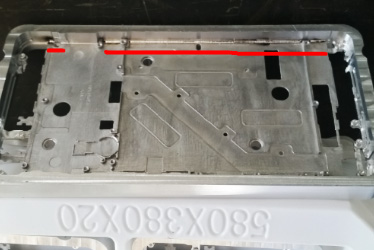

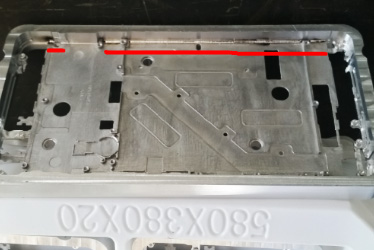

High-power laser welding machine welding aluminum material |

Laser head can be turned, can weld the mold deep cavity and mold side wall |

Mold laser welding machining principle

The principle of laser processing: the laser emitted by the laser generator passes through a series of processing, and the energy is highly concentrated in a small range after the lens focus. If the processed material absorbs the laser well, the material in the irradiated area will quickly heat up because of absorbing the energy absorption of the laser. Depending on the properties of the material (such as melting point, boiling point, the temperature causing chemical changes), the workpiece will undergo a series of physical or chemical changes, such as melting, gasification, generation of oxides, discoloration, and so on. This is the principle of laser processing.

Advanced processing mode, high efficiency

Compared with the traditional machining, the focused laser is like a very fine invisible tool, which "burns" the surface of the local area of the object point by point. It is characterized by no contact with the workpiece, no mechanical extrusion or mechanical stress, so it does not change the physical properties of the processed articles; because the size of the laser focusing is small, the thermal influence area is small, and the processing is fine, some conventional processes can be completed.

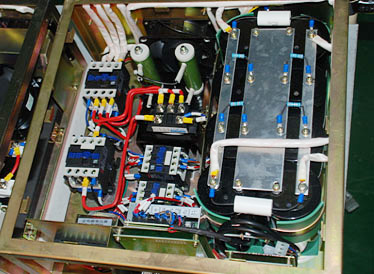

In-kind Shooting

Applied range

TFL-400 mold laser welding machine is a high-power laser welding machine independently developed by Tongfa Laser Company. It uses the second-generation precision double-lamp power supply independently developed by Tongfa to pump and drive the power supply with touch screen, and the operation is more convenient. The main engine has laser head hand lifting and work table button electric lifting to achieve laser welding of different thickness molds. This model is more suitable for all kinds of high-power, large-area laser repair mold. Due to high laser power, laser welding beryllium copper mold, aluminum mold or aluminum parts. In a large area of the laser repair mold, you can use a thicker welding wire, the laser welding efficiency is greatly improved.

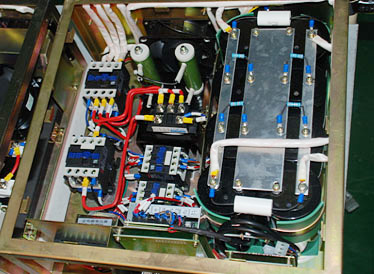

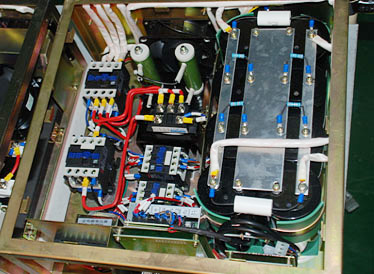

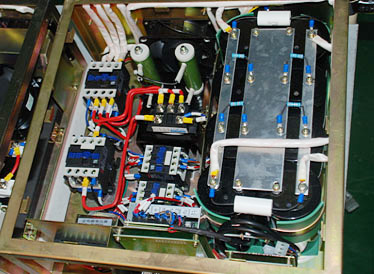

Precision power supply

The design mode of charging and discharge is adopted to reduce interference and further improve the working performance.

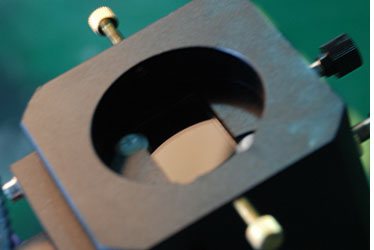

Core laser

Double-lamp gold chamber precision laser |

Gilded lamp clamlet, excellent conductivity without heat |

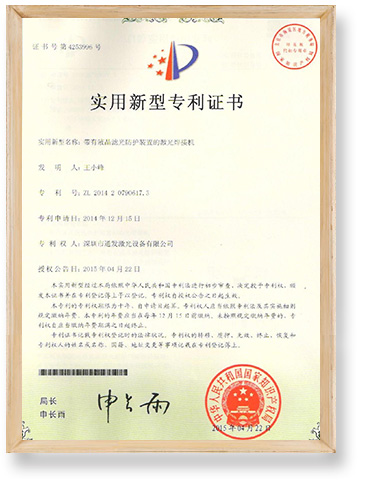

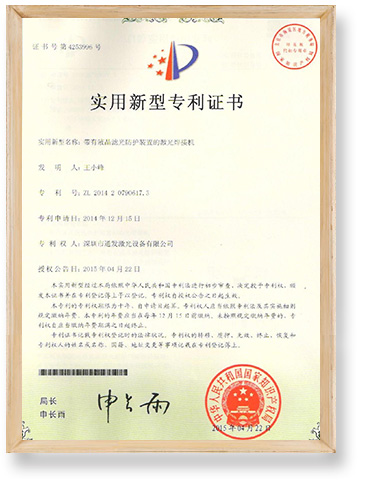

Model machine appearance patent and liquid crystal protection light brake patent

Machine appearance patent |

Liquid crystal protection brake patent |

|

Patent imitation flash eye LCD light lock |

Patent number:ZL201220267409.6 |

Independent patent: laser synchronous liquid crystal light lock device |

Protect the operator's glasses from laser stimulation |

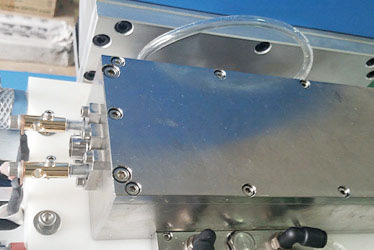

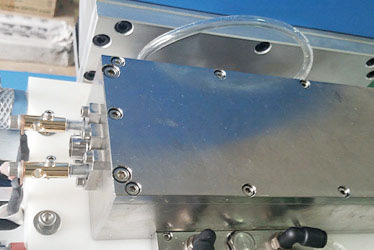

Parallel light-path microscopy

Parallel light path of the HD microscope photo |

Binocular pupil distance is adjustable, can be turned to observation |

Attachment and consumables

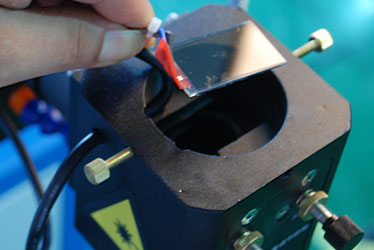

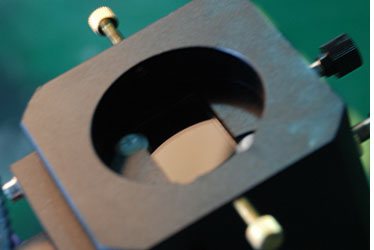

Open hair mold laser welding machine protection lens

Description of accessories: During the use of the mold laser welding machine, there will often be the phenomenon of iron splashing on the laser lens when melting. The lens plays a role in protecting the internal focusing lens. If there is too much iron adhesion to the protective lens affecting the laser power, the lens needs to be replaced.

|

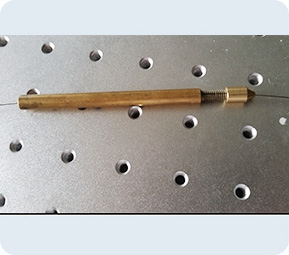

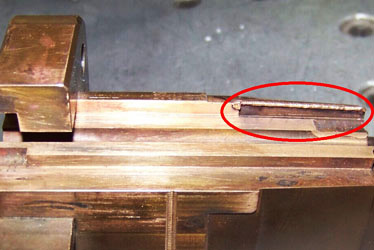

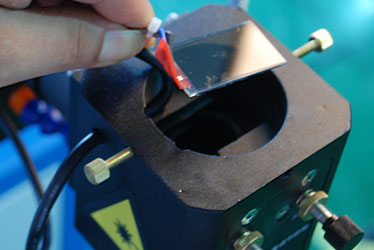

Mold laser welding machine welding wire pen

Parts description: this laser wire pen with a lock, can lock the 0.3-0.6 welding wire, especially for the case of deep hole and deep groove is not easy to hold the welding wire welding, welding wire pen plays a role in stable wire, is an indispensable tool for mold laser repair.

|

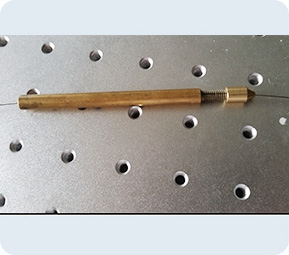

Mold laser welder foot switch

Description of accessories: in the use of laser welding machine, according to different situations, will continuously step, put the laser control foot, long time use will cause the aging or failure of the foot switch, found failure, consider replacing the foot switch.

|

Inlet die laser welding wire

Consumable description: This series of laser welding wire, imported from Germany, packaged by sealed plastic cylinder, mainly for laser repair welding of mold with high requirements, can meet the laser welding of mirror mold, nitride mold, high hardness mold and other molds.

|

Laser welding wire of the open mold

Consumable description: This series of laser welding wire, made of imported mold welding wire for fine processing, divided into different materials, can meet the laser repair welding quality of most molds, cost-effective.

|

Mold laser welder light bulb

Consumable description: lighting bulbs in use for a period of time, due to the life of the bulb, will appear aging or damage, need to be replaced in time.

|

Product Parameter

|

Model |

|

TFL-400Ⅲ |

|

laser wave length |

|

1064nm |

|

Concentration cavity reflector |

|

Import double lamp gold cavity |

|

Laser power |

|

400W |

|

Pulse length |

|

0.1-20ms |

|

Laser frequency |

|

0-99Hz |

|

The scope of light spot regulation |

|

0.3-3mm |

|

Coolant passage |

|

3p one-piece |

|

Table stroke |

|

125×100mm |

|

Rated effect |

|

14KW |

|

Electricity demand |

|

Standard three-phase 380v ± 5% / 50Hz / 40A |

|

External size |

|

Main machine: 680×1350×1400mm

Chiller: 600×900×1400mm |

Production strength

Huizhou Daya Bay self-built laser industrial Park |

Strong mass-production capacity |

After-sales guarantee

Adequate accessories inventory |

Standard material management |

Quality control

Strict quality control |

The quality of the recorded products can be traced back |