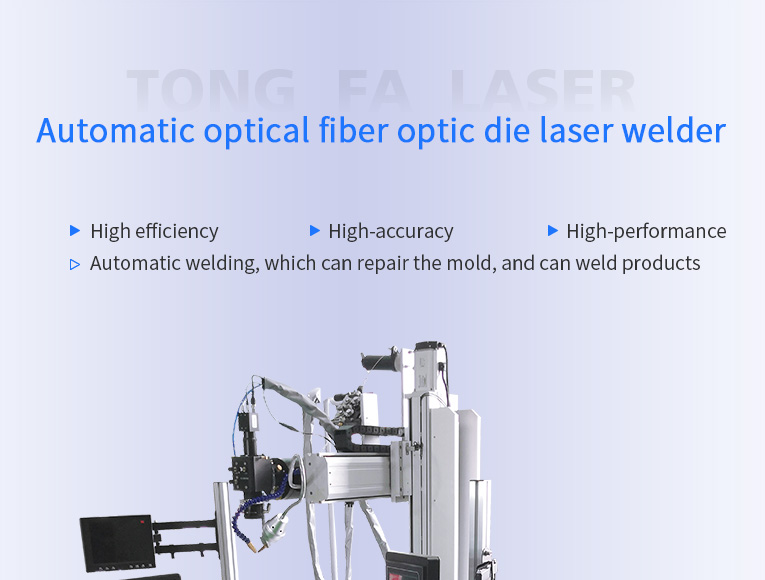

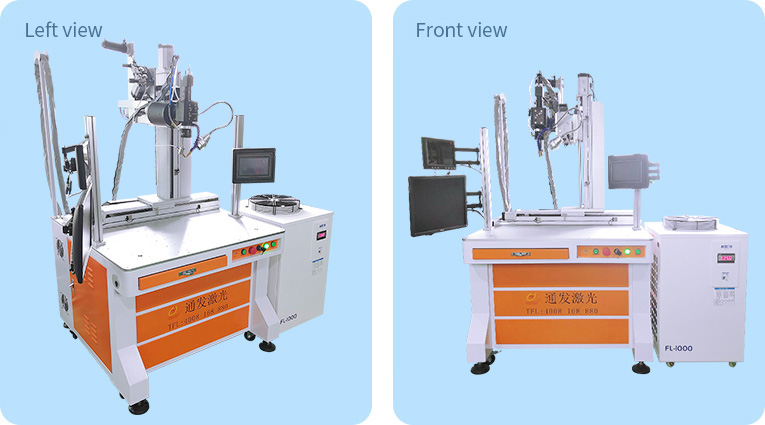

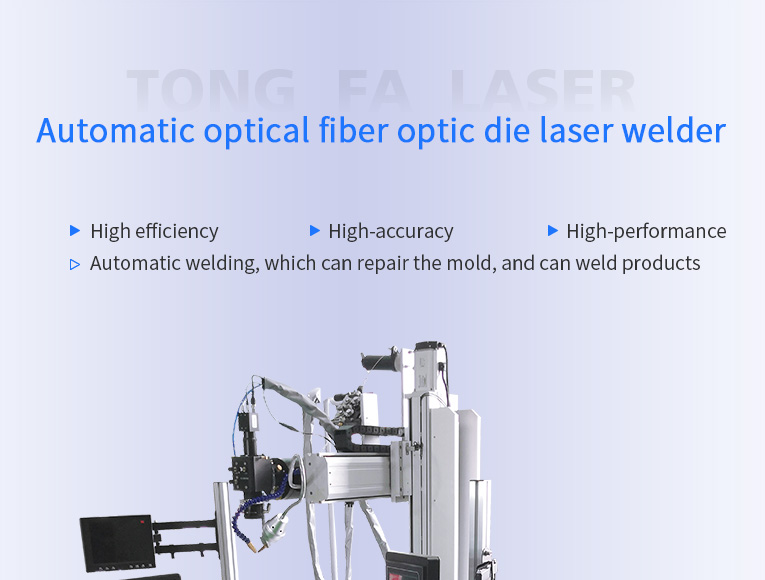

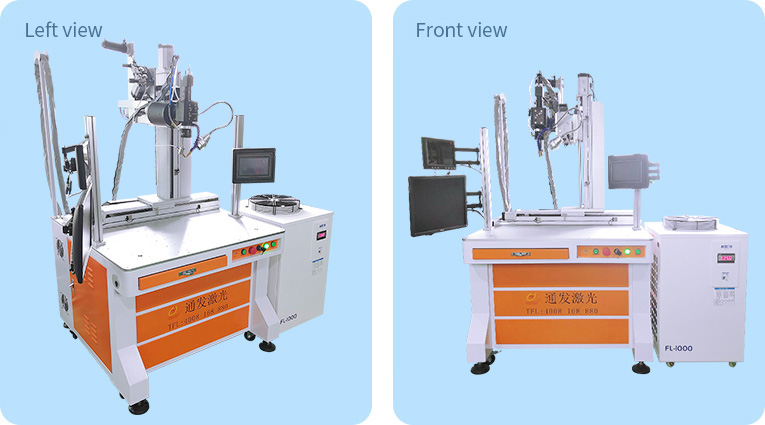

Picture of laser welding machine

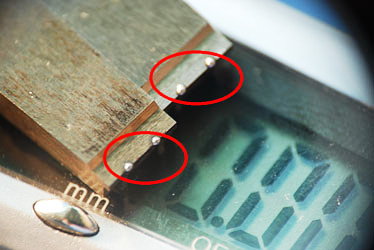

Titanium alloy products, laser automatic welding

|

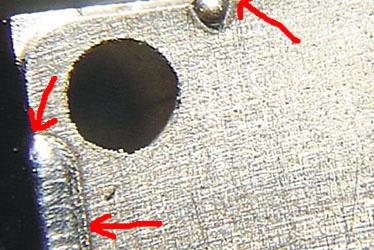

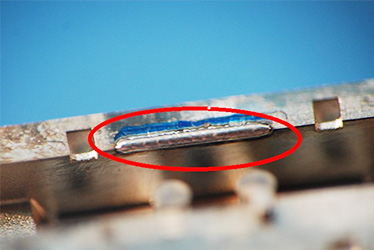

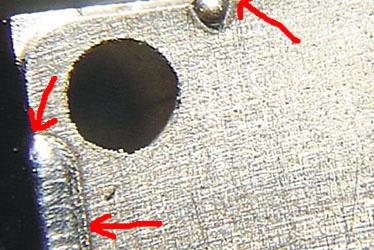

Mold precision insert sharp corner laser burn welding

|

Titanium alloy products, laser automatic welding

|

Laser welding corners of precision parts without damage, no bite edge

|

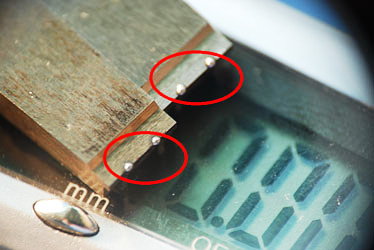

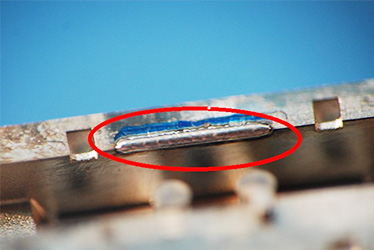

Laser welding of parts of injection mold

|

The laser head can turn, and the microscope can turn

|

Mold laser welding machining principle

The principle of laser processing: the laser emitted by the laser generator passes through a series of processing, and the energy is highly concentrated in a small range after the lens focus. If the processed material absorbs the laser well, the material in the irradiated area will quickly heat up because of absorbing the energy absorption of the laser. Depending on the properties of the material (such as melting point, boiling point, the temperature causing chemical changes), the workpiece will undergo a series of physical or chemical changes, such as melting, gasification, generation of oxides, discoloration, and so on. This is the principle of laser processing.

Advanced processing mode, high efficiency

Compared with the traditional machining, the focused laser is like a very fine invisible tool, which "burns" the surface of the local area of the object point by point. It is characterized by no contact with the workpiece, no mechanical extrusion or mechanical stress, so it does not change the physical properties of the processed articles; because the size of the laser focusing is small, the thermal influence area is small, and the processing is fine, some conventional processes can be completed.

In-kind Shooting

Applied range

Large precision injection molding, die casting die repair, beryllium copper mold, aluminum casting, sand hole, copper casting, air hole repair. Welding and supplementary welding processing of large-piece products.

Performance characteristics

1. The use of fiber laser, high reflectivity, strong energy, maintenance free, light free, less power consumption, compared to the traditional mold welding, small size, safety, good stability and long service life.

2.1500W fiber laser, to meet the needs of copper and aluminum welding large amount of mold and product welding processing, can repair the mold, but also welding products, but also optional handheld welding head.

3. High load-bearing base and workbench, maintain the advantages of light and flexible, while providing a higher carrying capacity.

4. Equipped with. The 1.5P high-power integrated water chiller ensures the stability of high-power welding.

|

Model |

TFL-1500DFA |

|

Laser wave length |

1070-1080nm |

|

Laser power |

1500W |

|

Laser device output stability |

±2% |

|

Fibre diameter |

50μm |

|

Fiber length |

10m |

|

Pumping source |

Semiconductor |

|

Beam quality |

≤1.1 |

|

Aiming at positioning |

Red light + CCD camera surveillance system |

|

Host power |

4.5KW |

|

Electricity demand |

220V±5%/50Hz |

|

Cooling-down method |

Water cooling 1.5P integrated |

|

Pulse length |

20MS |

|

Laser frequency |

1-50Hz |

|

Spot diameter |

≤1.0 |

|

Solder wire |

0.1-0.5mm |

|

Table stroke |

125*100mm |

Manufacturer actual shot